Tin recycling

Metal is the world’s most commonly recycled material. Tin sheet is 100%¹ recyclable and can be recycled any number of times without a loss of quality. New products are made from old products, which saves raw materials. One ton of recycled steel saves 1500 kg of iron, 650 kg of coal and 300 kg of limestone.¹

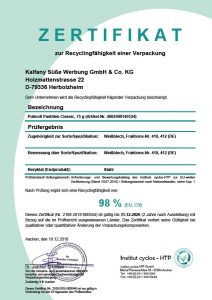

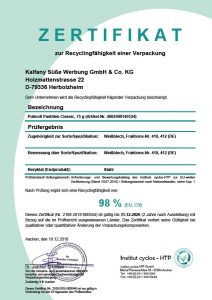

A new certificate from an expert appointed by the IHK (Chamber of Industry and Commerce) proves the almost 100% recyclability of the Pulmoll Classic tin and thus confirms the sustainable character of our tin packaging:

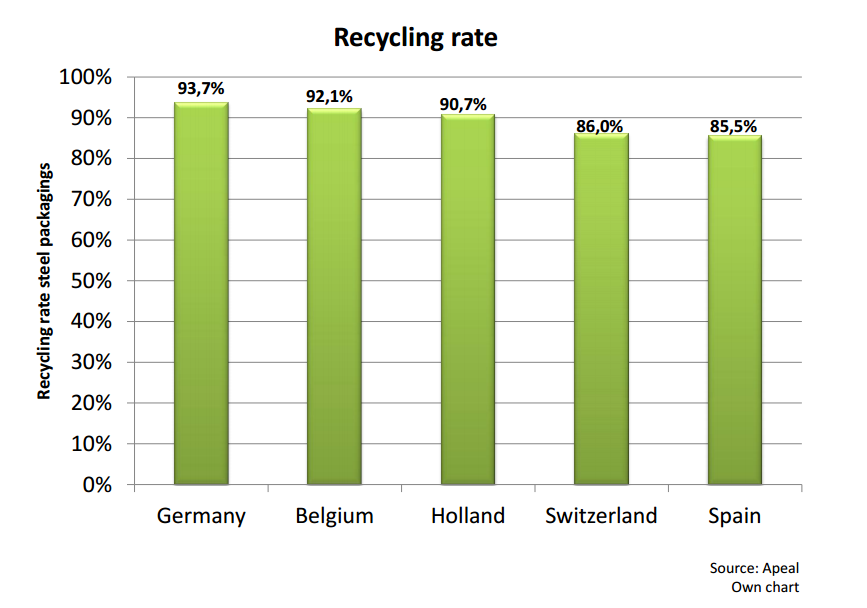

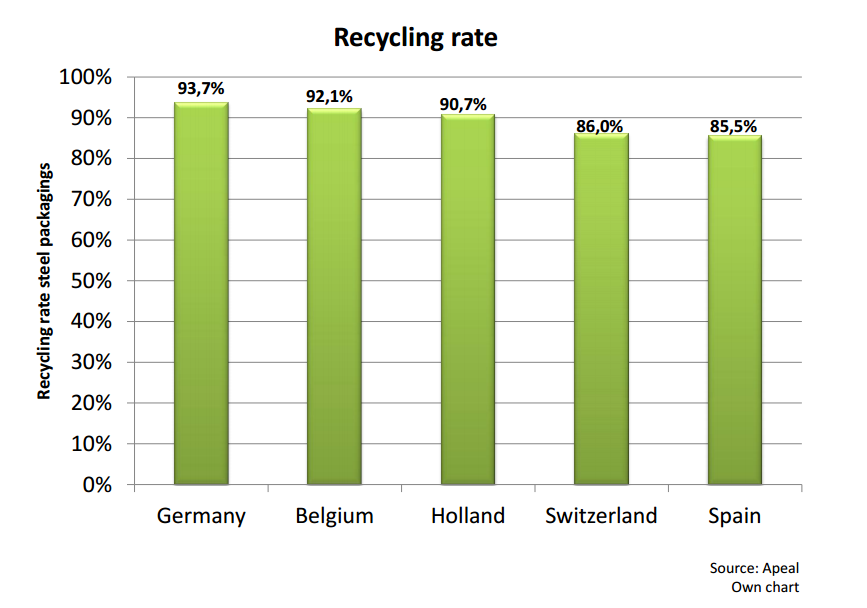

The recycling rate of the tin sheet tins (steel packagings) in Germany has been 93.7%¹ for years, creating a positive environmental balance. Recycling needs less energy than the manufacture of new products and hence less CO². For example when manufacturing steel from tin scrap, the energy consumption sinks 75%² and the CO2 emission is reduced by 80%.² No other packing material achieves better recycling rates. In comparison, even the recycling rate of glass is lower (87%).4 The upshot is that energy savings are the highest with tin sheet.

The recycling rate of the tin sheet tins (steel packagings) in Germany has been 93.7%¹ for years, creating a positive environmental balance. Recycling needs less energy than the manufacture of new products and hence less CO². For example when manufacturing steel from tin scrap, the energy consumption sinks 75%² and the CO2 emission is reduced by 80%.² No other packing material achieves better recycling rates. In comparison, even the recycling rate of glass is lower (87%).4 The upshot is that energy savings are the highest with tin sheet.

Since the launch of the Dual System, a total of 10.6 million tons² of tin sheet packagings have been recycled into new products. As a result for instance bicycles, cars or new metal packaging have emerged from the tins. The processing of the material cycle is accelerated through the use of magnetic conveyor belts, which lets our tins be recycled even more quickly. Germany saves 800,000 tons of iron ore and 360,000 tons of coal annually by recycling tin sheet.³

Apart from the positive environmental balance, our handy Pulmoll tins provide an excellent protective function against light, air and other influences, which maintains the unique taste of Pulmoll and guarantees the long shelf life of the pastilles.¹

Steel life cycle

The steel life cycle is used to elucidate the recyclability of tin sheet. It shows the steel resources along with the consumed energy and emissions from the production up through the end of life of a product, including recycling.

The steel life cycle is used to elucidate the recyclability of tin sheet. It shows the steel resources along with the consumed energy and emissions from the production up through the end of life of a product, including recycling.

Source:

¹APEAL

²Metallverpackungen.de

³DWR

4BGV Glas